How to Enhance Safety with Custom Food Conveyor System Design

In food manufacturing, speed, hygiene, and safety aren’t just priorities; they’re non-negotiable. Every moment on the production line demands precision. Every surface must be sanitary. And every movement needs to protect both product and personnel.

Yet many facilities still face two major safety risks: contamination from unsanitary equipment and injuries from repetitive motion or poorly designed conveyor components. These risks not only compromise product integrity and worker health, but they can also lead to costly downtime, compliance issues, and damaged trust.

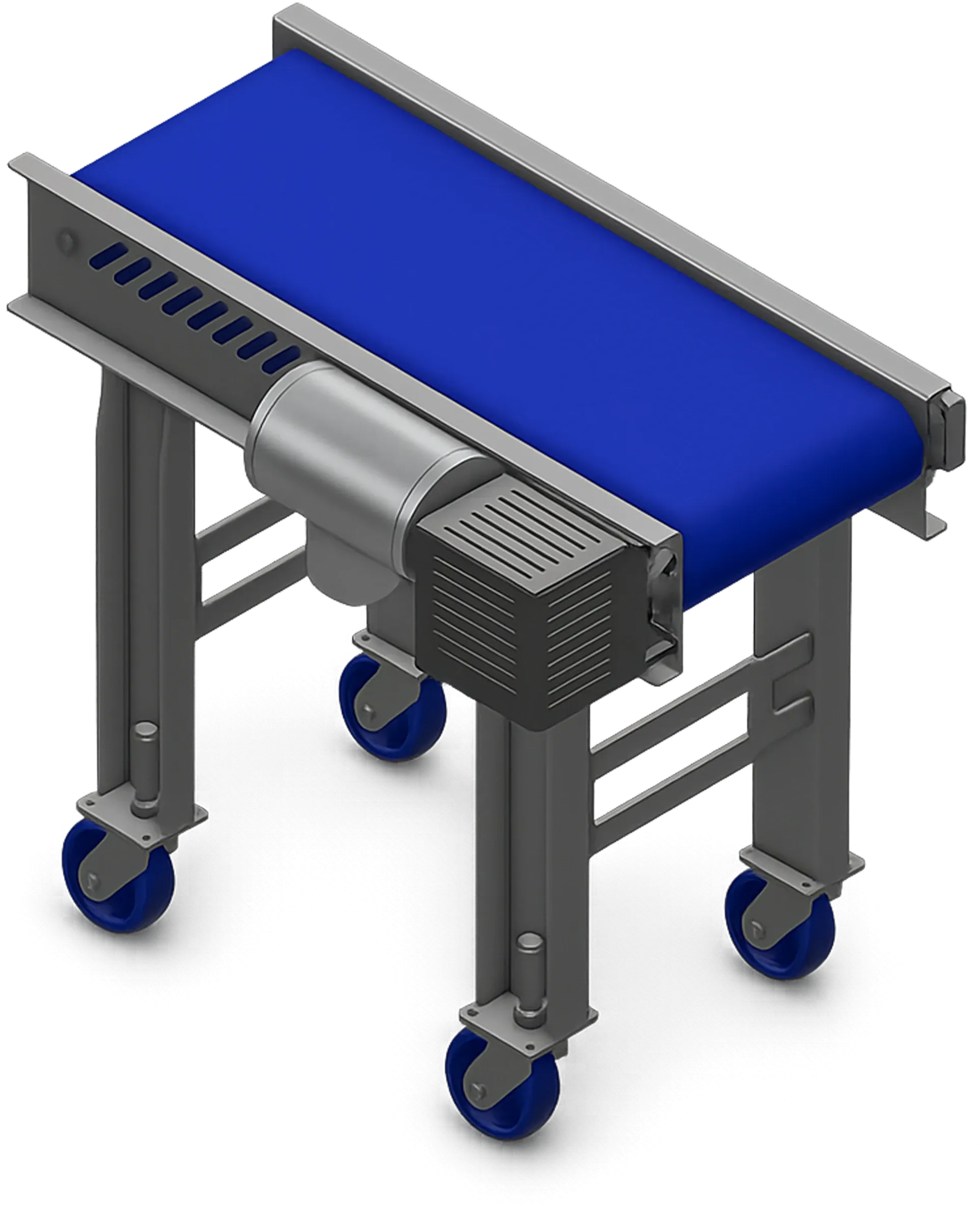

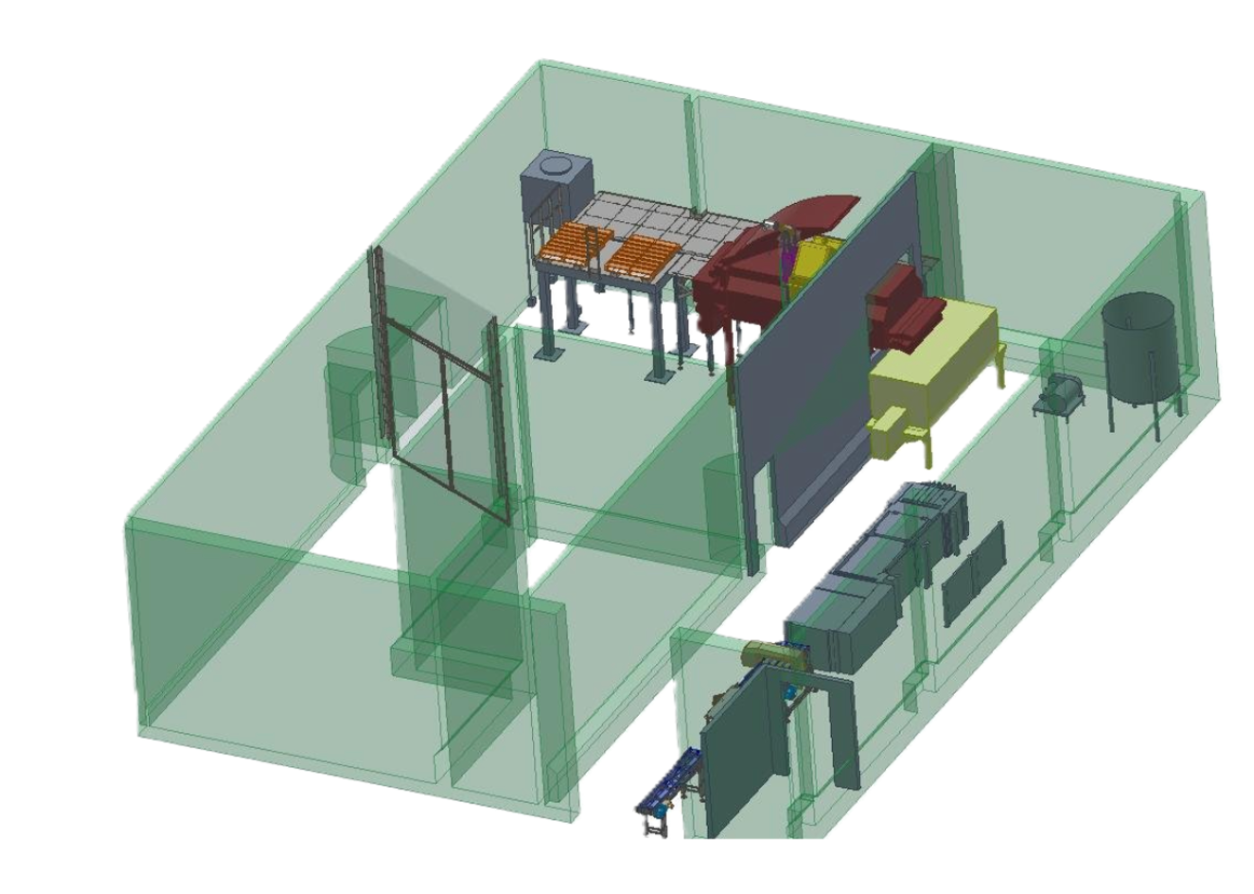

One of the most effective ways to address these challenges is by implementing a custom food conveyor system. Built to meet the exact needs of your production environment, a custom system is designed to reduce contamination risk and manual handling while improving overall safety and efficiency.

This article by

SCR Solutions explores how custom food conveyor system design enhances safety for both food and people—and how the right system can support long-term performance and peace of mind.

The Role of Food Conveyor Systems in Manufacturing

For seasoned professionals, a food conveyor system is more than a transport mechanism—it’s a strategic control point for safety, compliance, and efficiency. The real value lies in how well it balances hygienic design, cleanability, and system durability without compromising throughput.

Custom food conveyor systems allow you to engineer around known risks—whether minimizing allergen cross-contact, addressing audit findings, or improving access for sanitation crews. In modern operations, meeting FDA, USDA, and GMP standards isn’t enough; a well-designed conveyor must anticipate regulatory pressure and operational complexity.

Common Safety Hazards in Standard Conveyor Systems

Food Safety Hazards

Traditional systems can introduce several risks to product integrity, often relying on generic materials, limited sanitation access, and layouts that overlook contamination control:

- Bacteria buildup in crevices or on hard-to-clean surfaces can lead to contamination.

- Cross-contamination is common when shared belts or poor separation practices are used.

- Inappropriate materials, such as porous or reactive metals, may compromise sanitation.

Worker Safety Hazards

Operators also face increased risks when systems lack ergonomic design or essential safety features. Over time, this can lead to unsafe working conditions that compromise both health and productivity:

- Repetitive motion injuries often result from excessive bending, lifting, or twisting.

- Cuts and crush injuries can occur with unguarded or exposed moving parts.

- Slips and trips happen when layouts don’t account for waste management or foot traffic patterns.

How a Custom Food Conveyor System Improves Safety

How a Custom System Protects Food

Custom conveyor systems are built with hygiene at the forefront. They’re engineered to eliminate contamination risks before they arise, using design elements that support food safety, including:

- Hygienic, easy-to-clean materials reduce bacteria buildup and support sanitation.

- Open-frame structures and Clean-in-Place (CIP) designs allow for fast, effective cleaning without full system disassembly.

- Seamless transitions between equipment eliminate unnecessary product handling and reduce exposure to contamination.

- Automated controls and sensors help limit human contact with food, reducing the chance of introducing contaminants.

How a Custom System Protects Workers

Worker well-being is equally important. A thoughtfully designed food conveyor system helps create a safer work environment through:

- Ergonomic configurations that minimize lifting and reaching, reduce the risk of repetitive strain injuries.

- Guarded components that shield operators from moving parts, protecting against lacerations or crushing incidents.

- Smart automation that reduces repetitive manual tasks and alerts staff to potential safety hazards in real time.

- Simplified cleaning access, which minimizes risk during maintenance and sanitizing procedures.

Conclusion →

When safety is critical, the right system can transform your operation. SCR designs custom food conveyor systems specifically to increase safety in food manufacturing environments. Each system is built to support FDA, USDA, and GMP compliance while enhancing overall hygiene and efficiency by:

- Reducing contamination risks;

- minimizing manual handling;

- and improving ergonomic workflows across the line.

By choosing SCR, you’re partnering with a team that understands your safety challenges and delivers durable, long-term solutions tailored to your needs. Explore how

SCR’s food conveyor system design solutions

can enhance safety in your facility today!